Wat is er aan de hand, kinderen? Dit artikel heeft tot doel te praten over het gebruik van schuivende zaagmachines in het algemeen en waarom het belangrijk is om zaagbladen te maken van het juiste materiaal. Duidelijk, een schuivende zaag spreekt gewoonlijk over een specifiek gereedschap dat wordt gebruikt om dingen te snijden. Prestatie kan worden beïnvloed door verschillende bladmateriaalen ten opzichte van schuivende zagen onder andere factoren. Het kan ook de levensduur van het blad bepalen en hoeveel je ervoor moet betalen om het te verkrijgen. Is het niet interessant?

Verschillende bladen bestaan uit verschillende typen die samenwerken met de schuivende zagen

Sommige van de meest voorkomende materialen zijn hoge-snelheidsstaal, koolstaal en bi-metalen. Elk daarvan is goed op zijn eigen manier, terwijl ze ook enkele minder goede aspecten hebben. Een goed voorbeeld hiervan is hoge-snelheidsstaal. Hoge-snelheidsstaal is behoorlijk sterk en houdt zijn bruikbaarheid lang vast; daarom wordt het vaak door mensen verkozen--een beetje duur, maar niet zo geprijsd dat het iedereens eerste keuze zou zijn.

Aan de andere kant is koolstofstaal een goedkope alternatief waar de meeste mensen voor kiezen als ze niet te veel willen uitgeven. Maar staal is niet zo snel noch zo langdurig als hoge-snelheidsstaal. Bimetaal, dat bestaat uit een mengsel van hoge-snelheidsstaal en koolstofstaal, vormt een ander type. Het kan een goede balans bieden tussen kosten en kracht. Dit maakt het een slimme keuze voor vele.

Bladontwerp: De kern van de prestaties van een oscillerende zaag

Nu we hebben vastgesteld waarom het materiaal van het blad belangrijk is, laten we het hebben over het vorm- en formaat van het blad: het ontwerp van het blad. Het ontwerp van het blad kan een groot verschil maken in de prestaties van een zaag bij het snijden, wist je dat? Ja! Verschillende bladen zijn ontworpen voor verschillende taken.

Bijvoorbeeld, er zijn speciale werkstukkenbladen ontworpen voor hout. Deze bladen hebben specifieke vormen die ervoor zorgen dat ze in staat zijn om hout te doorboren en zonder problemen te snijden. Bladen hebben verschillende ontwerpen; die bedoeld zijn om metaal te snijden hebben andere ontwerpen bedoeld voor hardere materialen. Het ontwerp kan ook invloed hebben op hoe schoon de sneden zijn en hoe snel de zaag door het materiaal heen zal gaan.

Met een ideaal bladontwerp kunt u uw snij-/werkzaamheden volledig optimaliseren en zelfs versnellen. Als je sneden wilt die niemand aankan, kies dan voor een ongeschikt ontwerp. Je moet eerst het juiste ontwerp kiezen voordat je begint te snijden, omdat je jezelf anders erg gaat inzetten en vast komt te zitten in het snijproces.

Zorg ervoor dat je je materiaal en ontwerp kiest terwijl je ze toepast voor de juiste toepassing om optimale resultaten te behalen met je oscillerende zaag. Selecteer eerst de materialen die gesneden moeten worden en hoe vaak deze zaag in actie zal komen.

Als je de zaag vaak en gedurende een lange tijd gebruikt, is de optie hier om deze in een zeer hoge kwaliteit te krijgen, dus een waardevol blaadmateriaal zoals hoge-snelheidsstaal. Dit type kan echt veel gebruik verdragen en jarenlang uitstekend presteren. Aan de andere kant is koolstaal je beste alternatief als je de zaag zelden gebruikt en van het lage prijskaartje geniet. Het is niet zo duur en toch voldoende om iets met lichte gebruik te bereiken.

De Rol van het Blad in een Zaag: Hoe Snijkwaliteit Afhangt van de Samenspel Tussen Blad en Hulpmiddel

Zaagontwerp is extreem belangrijk omdat het verband houdt met hoe goed een zaag is en hoe goed deze zal snijden. Een uitstekend blad maakt schone, precieze sneden, wat het werken met de voegen veel makkelijker maakt. Dit maakt een project een stuk netter en een stuk gemakkelijker af te ronden.

Terwijl een slechte ontwerp, aan de andere kant, de sneden rommelig zal maken, voor zover mogelijk. Bijvoorbeeld, messen met zeer kleine tanden zijn perfect om hardere materialen te snijden, zoals metaal. Ze werken omdat ze het materiaal stevig kunnen vasthouden. Maar deze kleine tanden werken niet zo goed bij het snijden van zachtere materialen zoals hout.

Zagen met grotere tanden zijn beter geschikt voor zachte en vochtige materialen, omdat ze niet zo gemakkelijk doorsnijden. Toch moeten ze worden gezien als minder geschikt voor harde materialen. Dus weten wat het juiste blaadjeontwerp is voor het materiaal zal veel bijdragen aan een correcte snede.

In een notendop dit-hoe blaadmateriaal en prestaties in oscillërende zagen vergeleken moeten worden. Je maakt een zaag waarschijnlijker om goede, schone sneden te produceren door specifiek bladmateriaal en -ontwerp te gebruiken dat het beste geschikt is voor de taak die je moet uitvoeren.

Dus, terwijl je kiest om een nieuwe oscillerende zaag te kopen, moet ernstig worden overwogen hoeveel de materiaalsoort en de vorm van de zaagbladen moeten meespelen in zo'n keuze. En als je een zaag hebt waar je ontevreden over bent, probeer dan eerst een andere zaagblaadse om te zien of dat het probleem oplost.

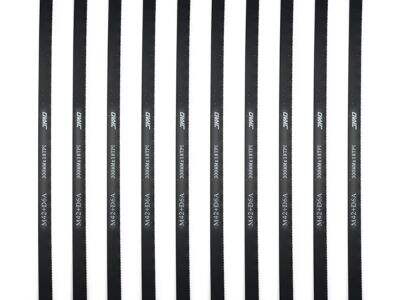

JMD heeft een verscheidenheid aan oscillerende zaagbladen met de beste materialen voor verschillende soorten. We hebben de bladen gemaakt voor alle soorten van materialen, of het nu hout, metaal of enige andere soort is. Dus, waarom geef je ons niet een kans? Je zult misschien verbaasd zijn over het verschil dat een juist zaagblad kan maken!

NL

NL

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

ET

ET

HU

HU

TR

TR

FA

FA

GA

GA

CY

CY

BE

BE

IS

IS

HY

HY

AZ

AZ

KA

KA

LA

LA

MY

MY

XH

XH