If you have ever cut metal, wood or anything tough with a hacksaw. The work is hard, it can often be drawn out to the n-th degree. Enter the tungsten carbide hacksaw blades. Those special blades really cut down the cutting time and effort in a significant way! Read on to get the lowdown everything from usefulness of these blades.

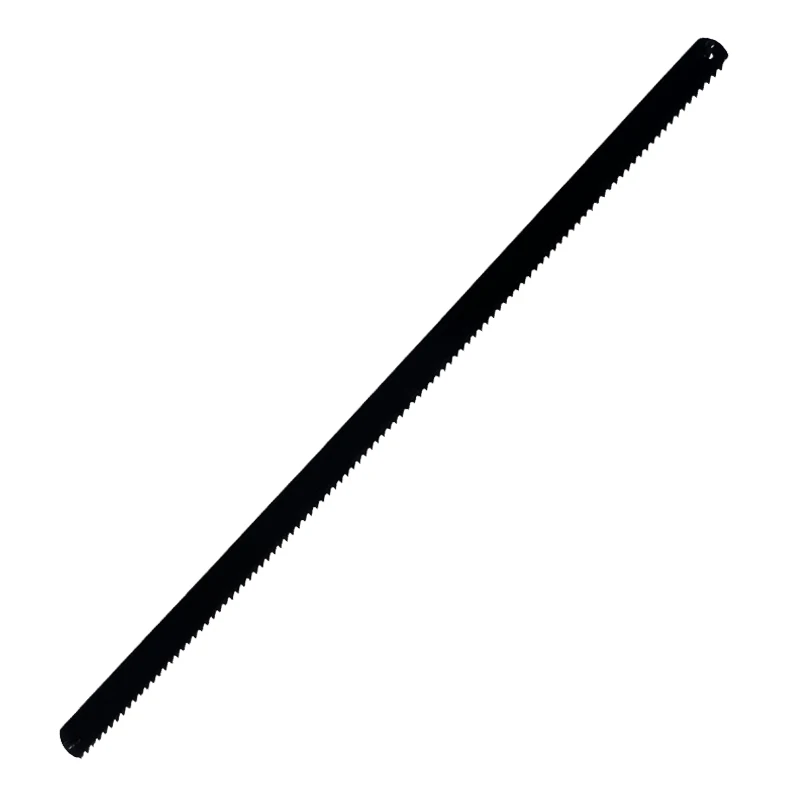

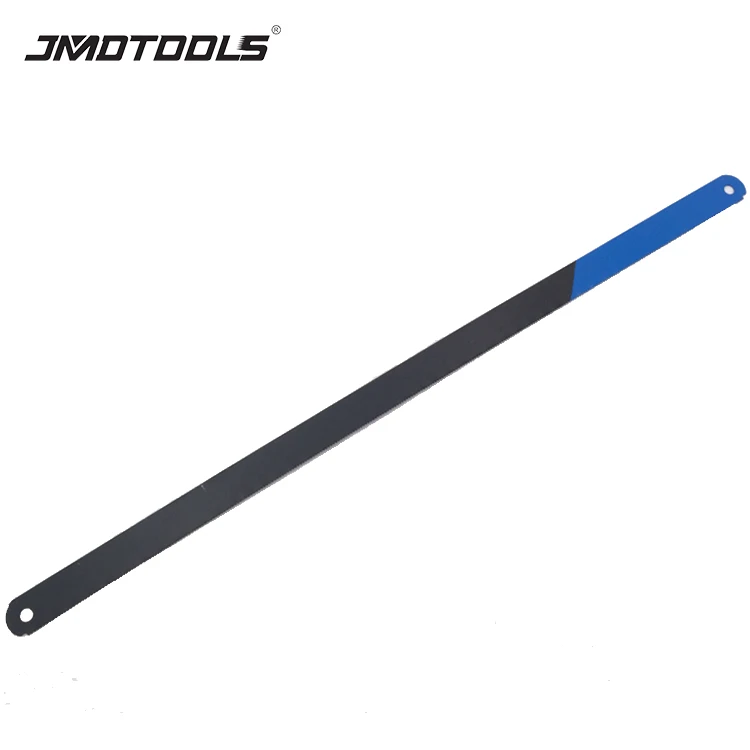

Tungsten carbide in on the strongest materials, and it is frequently used to make cutting tools. Tungsten carbide is a valuable cutting tool when it developed for hacksaw blade production used to cut metal, plastic or wood. Since a hacksaw blade is thin and flexible, it can flex a bit during use. Tiny teeth run down the edge of the blade, which make small cuts when you pull it back and forth over a material to cut. Tungsten carbide hacksaw blades have teeth that are much more resilient than those on a standard hacksaw blade, so it will allow you to make your cuts quickly and with greater efficiency.

This allows you to finish your job much quicker if you make use of tungsten carbide hacksaw blades. These blades are best used for material like steel or iron, the types of metal that aren't necessarily your go-to cutting tasks. It can be really annoying as regular hacksaw blades tend to break or wear out very quickly when you try cutting through these hard materials. But the good news is, tungsten carbide blades are built for this kind of tough work! They last much longer than conventional blades, resulting in less blade changesrequired ever. That way, you can keep working and complete your project with minimal interruptions.

There are countless great benefits to using tungsten carbide hacksaw blades instead of other types of saws. To begin, these blades are still sharp after extensive use. This means that you will not have to stop working in order to switch out the blade (as frequently as you would with a standard hacksaw blade) The second would be the strength as they are made a lot more stronger than regular blades so that you can actually cut tougher materials and not bend or break your blade. This is essential when you are working with large projects. Finally, tungsten carbide blades ensure clean and accurate cuts resulting in reduced sanding or finishing required on the cut. This will save you even more time and effort!

After you learned to make the cut with that hack saw but had a jagged or crooked edge? It can be really annoying and make the project appear sloppy! Instead, you get much cleaner cuts with tungsten carbide hacksaw blades. Those little teeth on the blade edge may look thin, but they are stronger than that of a standard hacksaw. Thus, they are able to create the incision with precision in brittle materials as well. Whether you are looking for a smooth, clean cut with minimal errors or if your only objective is to reduce the amount of chipping that occurs during tool applications; Knows about how Handy said these razor blades can be!

So, if you are done with the fumbling nature of traditional hacksaw blades that never work right – it is time to rip them out and upgrade your blade game using tungsten carbide hacksaw blades. While the blades might be a tad more expensive than regular blades, they pay for themselves in no time. Having a proper blade will avoid the frustration and time suck entirely. Also, they are strong and accurate drastically help you to perform the cuts that you did not believe were possible. For sure it will change your level of cutting projects!

We employ a group of highly skilled technicians who are committed to pursuing cutting-edge technology throughout the year. The team zealous about innovation and always in search of most recent trends market and customer demands. Their experience allows the company to develop new products that not just match but surpass the expectations of the market. We ensure that our products are always current tungsten carbide hacksaw blade by keeping up-to-date with the latest trends. We able to offer unique solutions through investment in R and D.

Our factory has gained invaluable information and experience working with leading brands and customers the industry for more 20 years. The extensive experience has allowed us to comprehend the specific requirements and demands our clients. This allows us create custom solutions and services. Through a number of successful partnerships we refined our production procedures, improved the quality control processes, and developed deep tungsten carbide hacksaw blade of the market's developments. Our long-standing standing in business is result of our dedication to excellence and our ability deliver consistently high-quality services products.

In our production process, have implemented exceptionally strict quality inspection process. Every stage tungsten carbide hacksaw blade monitored and checked to ensure only the finest products leave our factory. Our quality control staff is equipped with state-of-the-art testing equipment adheres strict guidelines to conduct thorough testing of products. This methodical approach enables us to spot any potential problems products and rectify these before our products can reach our customers. We assure our clients' satisfaction maintaining strict high standards quality. This allows us to build relationships built on trust and reliability.

We are very proud of being able to pass the ISO9001:2015 quality certification, in addition to BSCI and BEPI certifications. These certifications testify of our commitment to maintaining the top-quality standards ethical sourcing, ethical purchasing, and environmental accountability. The ISO9001:2015 certificate ensures that quality management systems are robust and efficient, which turn guarantees high quality products that are consistent. The BSCI certification and BEPI certificate prove our dedication to sustainability and social compliance business practices. This gives our customers confidence that the products they purchase were made using ethical sustainable conditions.