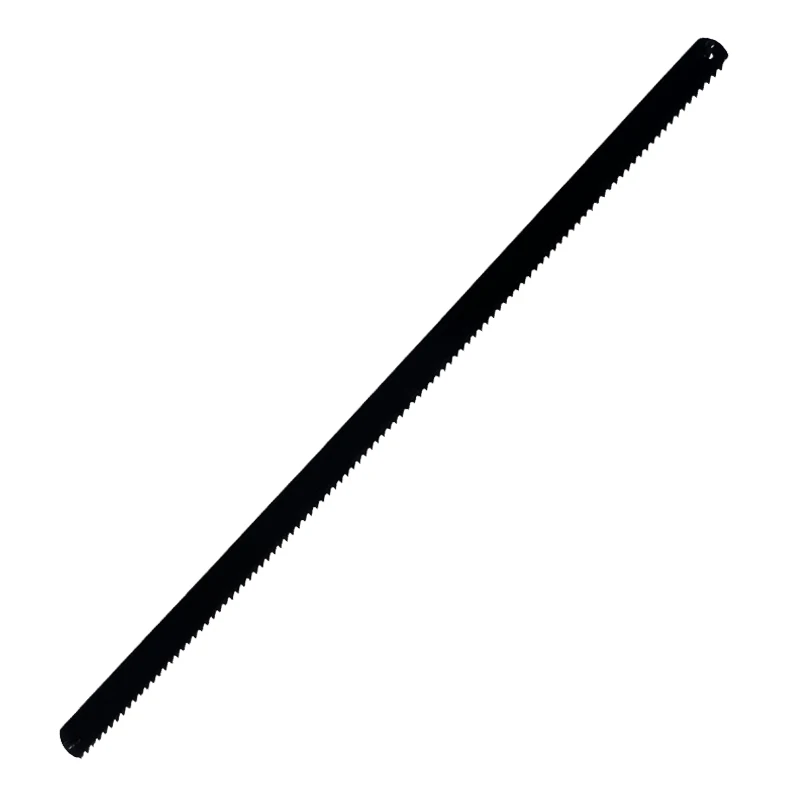

Here are factors to consider when deciding which hacksaw blade is right for your next project. The very first thing you need to consider is what material will be cut Blades are made for cutting different materials so you have a metal blade, wood blade as well as plastic and more. Choosing the right blade is very important if you want to cut a certain material and save both your workpiece, but also labour of your saw.

Aside from the material, you should also take into account the blade's tooth pattern. Each blade has a different number of teeth per inch (TPI) and this determines how efficiently the cutting ability is. If you are cutting thin metal then the blade with high TPI is suitable but for thick metals, a low-TPI blade can make good cuts.

In order to keep your life hacksaw blade working correctly over time it must be maintained properly. Afterward, make sure to wipe and clean the blade thoroughly with alcohol before storing it back in a dry place where nothing can happen. When you see signs of wear, replace the blade right away. Even further, the right amount of pressure and a lubricant can help to cut even more smoothly as well.

In case the hacksaw blade become dull before it is time to replace, then you can try some of these DIY tricks for sharpening. You can restore the blade if you sharpen it at a 45-degree angle using either file, grinder or whetstone to heat it.

Although the hacksaw blade may be regarded as a tool that can cut metal, it is not restricted to only cutting through metals like aluminum and steel but also for other materials including wood, plastic and even ceramic. Selecting the right tooth pattern is vital as this makes it possible to achieve immaculate outcomes depending on material thickness. Blades with lower TPI are ideal if you need to cut through thicker materials; however, those that have higher TIP will do the trick for thinner materials. On top of that, blades which have a variable TPI are able to perform well on different materials.

With careful blade selection, maintenance practices, and cutting methods for your hacksaw blade, you can ensure that it is put to the best use over its wide range of projects throughout its lifetime.

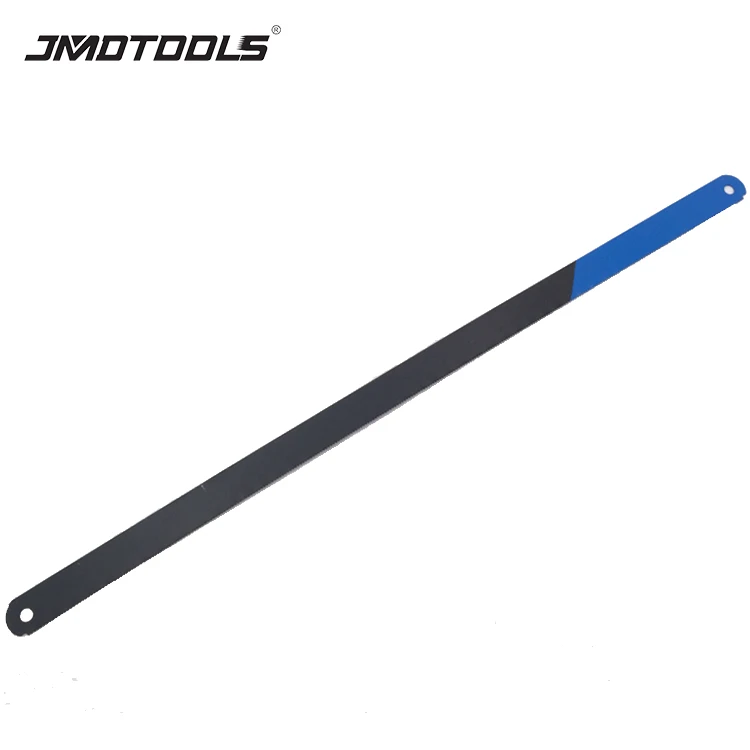

Our team consists of highly-trained technicians are committed to pursuing cutting-edge technology throughout entire year. This team is committed innovation and always looking out for the latest trends in the marketplace. Their knowledge and experience allow the company to develop new products that not just satisfy also exceed requirements of the market. We make sure that our products are always hacksaw blade and competitive by keeping up-to-date with the latest trends. Continuous effort in R and D will allow us to develop unique solutions while remaining at the top our game.

With more than 20 years of experience working well-known brands and clients in business, our manufacturing facility accumulated invaluable expertise and insight. Our vast experience enabled us to understand the unique needs of our customers and expectations, which allows to provide customized solutions and services. Through number of successful partnerships we've refined production processes, improved hacksaw blade control processes, and developed a deep understanding of the market's changes. Our long-standing standing the field is a testament of commitment to excellence as well as our capacity consistently deliver superior products and services.

We are proud to having successfully passed the ISO9001:2015 quality certification, along BSCI and BEPI certifications. These certifications prove our dedication to the highest standards of quality ethical sourcing, ethical sourcing and environmental accountability. The ISO9001:2015 certificate ensures that quality control systems are robust and efficient which, in turn, hacksaw blade consistent product quality. The BSCI and BEPI certifications demonstrate our dedication to social compliance and sustainable business practices. It provides our customers with confidence that our products are made in environmentally-friendly and ethical conditions.

In manufacturing process, we have implemented strict quality inspection process. Every stage of manufacturing is carefully monitored scrutinized ensure that only products of the highest quality leave our factory. Our quality control team uses the most modern testing equipment test products thoroughly. This methodical hacksaw blade allows to spot any potential quality issues and fix the issues before our products are delivered to our customers. We ensure customers' satisfaction by ensuring that we adhere to strict quality standards. This allows to establish relationships are based on trust reliability.